|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

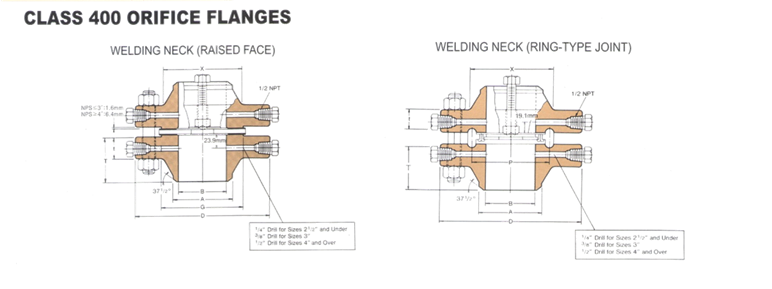

| ANSI

B16.36 FORGED FLANGES |

|

|

|

|

|

Unit: mm |

|

|

|

|

|

|

|

|

|

|

|

|

|

| Class

400 Orifice Flanges |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Nominal Pipe Size |

Outside Diam of Flange |

Thickness of Flange (1) |

Diam of Hub at base |

Diam of raised face |

Diam of Hub Bevel |

Length thru Hub (1) |

Bore (B) |

Pitch Diam of Ring and Groove |

Ring Number |

Depth of jack screw slot |

Depth of jack screw slot |

Drilling Template |

Nominal Pipe Size |

| Raised Face |

Ring Joint |

Welding Neck |

Slip- on & threaded |

Welding Neck |

Slip- on |

Raised face |

Ring Joint |

Raised face |

Ring Joint |

Diam of bolt circle |

Number of Bolts |

Diam. Of Stud Bolts (inch) |

Diam. Of Bolt Holes |

Length of stud bolts |

| D |

X |

G |

A |

Raised Face |

Ring joint |

Raised Face |

Ring joint |

P |

Raised face |

Ring Joint |

| 1 |

124 |

38.1 |

31.8 |

53.8 |

50.8 |

35.5 |

82.6 |

76.2 |

47.8 |

41.1 |

See Note (1) to be specified by purchaser |

34.5 |

50.8 |

R16 |

9.7 |

6.4 |

5/8×4.00 |

5/8×4.75 |

88.9 |

4 |

5/8 |

17.5 |

127.0 |

146.1 |

1 |

| 1 ¼ |

133 |

38.1 |

31.8 |

63.5 |

63.5 |

42.2 |

84.1 |

77.7 |

46.0 |

39.6 |

43.2 |

60.3 |

R18 |

9.7 |

6.4 |

5/8×4.00 |

5/8×4.75 |

98.6 |

4 |

5/8 |

17.5 |

127.0 |

120.7 |

1 ¼ |

| 1 ½ |

155 |

38.1 |

31.8 |

69.9 |

73.2 |

48.3 |

85.9 |

79.2 |

47.8 |

41.1 |

49.5 |

68.3 |

R20 |

12.7 |

6.4 |

¾×4.25 |

¾×5.00 |

114.3 |

4 |

3/4 |

21.0 |

133.4 |

152.4 |

1 ½ |

| 2 |

165 |

38.1 |

31.8 |

84.1 |

91.9 |

60.5 |

85.9 |

79.2 |

49.3 |

42.9 |

62.0 |

82.6 |

R23 |

9.7 |

6.4 |

5/8×4.00 |

5/8×4.75 |

127.0 |

8 |

5/8 |

17.5 |

127.0 |

152.4 |

2 |

| 2 ½ |

191 |

38.1 |

31.8 |

100.1 |

104.6 |

73.2 |

88.9 |

82.6 |

50.8 |

44.5 |

74.7 |

101.6 |

R26 |

12.7 |

6.4 |

¾×4.25 |

¾×5.00 |

149.4 |

8 |

3/4 |

20.6 |

133.4 |

158.8 |

2 ½ |

| 3 |

210 |

38.1 |

31.8 |

117.3 |

127.0 |

88.9 |

88.9 |

82.6 |

52.3 |

46.0 |

90.7 |

123.8 |

R31 |

12.7 |

6.4 |

¾×4.25 |

¾×5.00 |

168.1 |

8 |

3/4 |

20.6 |

133.4 |

158.8 |

3 |

| 4 |

254 |

35.1 |

35.1 |

146.1 |

157.2 |

114.3 |

88.9 |

88.9 |

50.8 |

50.8 |

116.1 |

149.2 |

R37 |

6.4 |

15.7 |

¾×3.00 |

¾×4.00 |

200.2 |

8 |

7/8 |

25.4 |

139.7 |

152.4 |

4 |

| 5 |

279 |

38.1 |

38.1 |

177.8 |

185.7 |

141.2 |

101.6 |

101.6 |

53.8 |

53.8 |

143.8 |

181.0 |

R41 |

6.4 |

15.7 |

¾×3.00 |

¾×4.00 |

235.0 |

8 |

7/8 |

25.4 |

146.1 |

158.8 |

5 |

| 6 |

318 |

41.1 |

41.1 |

206.2 |

215.9 |

168.4 |

103.1 |

103.1 |

57.2 |

57.2 |

170.7 |

211.1 |

R45 |

12.7 |

22.4 |

1×3.50 |

1×4.00 |

269.7 |

12 |

7/8 |

25.4 |

158.8 |

165.1 |

6 |

| 8 |

381 |

47.8 |

47.8 |

260.4 |

269.7 |

219.2 |

117.3 |

117.3 |

68.3 |

68.3 |

221.5 |

269.9 |

R49 |

12.7 |

22.4 |

1×3.50 |

1×4.50 |

330.2 |

12 |

1 |

28.4 |

171.5 |

184.2 |

8 |

| 10 |

445 |

53.8 |

53.8 |

320.5 |

323.9 |

273.1 |

124.0 |

124.0 |

73.2 |

73.2 |

276.4 |

323.9 |

R53 |

12.7 |

22.4 |

1×4.00 |

1×4.50 |

387.4 |

16 |

1 1/8 |

31.8 |

190.5 |

203.2 |

10 |

| 12 |

521 |

57.2 |

57.2 |

374.7 |

381.0 |

323.9 |

136.7 |

136.7 |

79.2 |

79.2 |

327.2 |

381.0 |

R57 |

12.7 |

22.4 |

1×4.00 |

1×5.00 |

450.9 |

16 |

1 ¼ |

35.1 |

203.2 |

215.9 |

12 |

| 14 |

584 |

60.7 |

60.7 |

425.5 |

412.8 |

355.6 |

149.4 |

149.4 |

|

359.2 |

419.1 |

R61 |

12.7 |

22.4 |

1×4.25 |

1×5.00 |

514.4 |

20 |

1 ¼ |

35.1 |

209.6 |

228.6 |

14 |

| 16 |

648 |

63.5 |

63.5 |

482.6 |

469.9 |

406.4 |

152.4 |

152.4 |

410.5 |

469.9 |

R65 |

12.7 |

22.4 |

1×4.25 |

1×5.00 |

571.5 |

20 |

1 3/8 |

38.1 |

222.3 |

235.0 |

16 |

| 18 |

711 |

66.5 |

66.5 |

533.4 |

533.4 |

457.2 |

165.1 |

165.1 |

461.8 |

533.4 |

R69 |

12.7 |

22.4 |

1×4.50 |

1×5.00 |

628.7 |

24 |

1 3/8 |

38.1 |

235.0 |

241.3 |

18 |

| 20 |

775 |

69.9 |

69.9 |

587.2 |

584.2 |

508.0 |

168.1 |

168.1 |

513.1 |

584.2 |

R73 |

12.7 |

22.4 |

1×4.75 |

1×5.50 |

685.8 |

24 |

1 ½ |

41.1 |

247.7 |

260.4 |

20 |

| 24 |

914 |

76.2 |

76.2 |

701.5 |

692.2 |

609.6 |

174.8 |

174.8 |

564.4 |

692.2 |

R77 |

12.7 |

22.4 |

1×5.00 |

1×6.00 |

812.8 |

24 |

1 ¾ |

47.8 |

279.4 |

285.8 |

24 |

| Notes: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| (1)

For the inside diameter of Pipes (corresponding to Bore (B) of welding Neck

Flanges), refer to 54. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| (2)

Class 400 flanges of size 3" and smaller will be furnished with

0.06" (1.6mm) raised face, which is included in |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| thickness

(t) and length through Hub (T) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| The

0.25" (6.35mm) raised face for sizes 4" and larger is not included

in (t) and (T) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| (3)

Each union includes two carbon steel jack screw bolts with hex nuts. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| (4)

Unless otherwise specified, raised face union are furnished with alloy bolt

studs per ASTM A193 Grade B7 with American. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Standard

heavy series hex nuts ASTM A197 Class 2H. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| (5)

On ring joint flanges having a groove depth 0.375" (9.5mm) and less, the

distance from the center line of the tap hole to the flange |

|

|

|

|

|

|

|

|

|

|

|

|

|

| face

is 0.750" (19.1mm) when the depth of groove is 0.438" (11.1mm) or

greater, changes in drill size or method of drilling are necessary. |

|

|

|

|

|

|

|

|

|

|

|

|

|

| (6)

Bolt lengths for raised face flanges include allowance for orifice and gasket

thickness of 0.25" (6.4mm) for sizes 4-12 and |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 0.38"

(9.7mm) for sizes 14-24. bolt lengths for ring type joint flanges include

allowance of 0.62" (15.7mm) for sizes 4-10 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 0.75"

(19.1mm) for sizes 12-18 and 0.88" (22.4mm) for size 20. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|